Plastic Container

Industry

Follow this link to read about relevant industry developments

Services

The experts at Apex Container Tech Inc. are here to assist you in your current business or with starting a new one

The experts at Apex Container Tech Inc. are here to assist you in your current business or with starting a new one

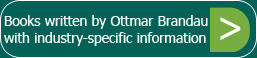

Supplying equal water pressure and optimal flow to each blow mold or injection mold machine is extremely important for best cooling parameters and cycle times. In the standard lay-out on the picture below, the pressure drops as the water gets further away from the chiller leaving machine 1 at a reduced rate of cooling. This situation can be rectified by installing individual flow controls to each machine and/or installing booster pumps to increase water pressure at the machines further away from the chiller. However, this solution introduces mechanical-electrical components that are subject to failure and mis-adjustment.

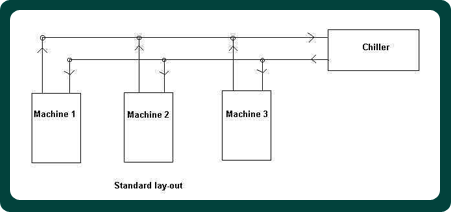

A very elegant and inexpensive solution that provides nearly as much control is the installation of a looped return. This piping assures that the water to each machine travels the same distance to and from the chiller, thus equalizing pressure and flow.

A very elegant and inexpensive solution that provides nearly as much control is the installation of a looped return. This piping assures that the water to each machine travels the same distance to and from the chiller, thus equalizing pressure and flow.

Comprehensive services to develop your package in any blow molding technology

Stretch blow molding is one of the areas our expertise covers. Examine our offerings

Our expert advice in this area has helped many companies improve their bottom line

Injection stretch blow molding is a complicated process that often requires our expert advice